Menu Covers: First Impressions Count In Defining Your Customer’s Dining Experience

A menu cover is your first opportunity to connect with your customer. In this article, we’ll guide you through creating

A menu cover is your first opportunity to connect with your customer. In this article, we’ll guide you through creating

Maintaining the highest standards of food quality, taste, and safety is crucial in the dynamic world of hospitality and culinary

Champagne is often associated with celebrations and special occasions, and for good reason.

When it comes to crafting the perfect cup of coffee, every detail matters. From the quality of the beans to

In hospitality, maintaining the highest standards of quality and safety is essential. An overlooked crucial aspect is effective stock management and date labelling. Ensuring your ingredients and products are used at their peak freshness while adhering to use-by dates can make or break your business. This guide will take you through the essential strategies and best practices to master stock management and rotation, all while utilising adequate date labelling.

It’s a crucial aspect of inventory management, particularly in food service establishments like restaurants, hotels, and catering companies. The primary goal of the stock rotation is to ensure the freshness and quality of products while minimising waste.

The FIFO (First-In, First-Out) method is commonly used, where the oldest stock is placed at the front of the shelf or in an easily accessible storage area. This ensures that items with impending sell-by dates are used or sold first, reducing waste.

The first step to effective stock management is implementing a stock rotation system. This involves organising inventory so that older products are sold or used first. Here is a quick step-by-step guide to implement it in your business.

| Steps | Description |

| Inventory Check | Regularly check and record all existing stock. |

| Label Products | Regularly check and record all existing stock. |

| FIFO System | Implement the “First In, First Out” (FIFO) system. |

| Organised Storage | Organise your storage areas with the oldest products at the front for easy access. |

| Staff Training | Train your staff on the importance of stock rotation and how to identify products by their expiration dates. |

| Regular Audits | Conduct routine audits to ensure compliance. |

| Remove Expired Items | Promptly remove and document expired products. |

Training staff in the correct stock rotation processes is essential. Employees should know the different shelf lives of products and the importance of rotating stock. Regular training sessions can help ensure all team members are up-to-date with the latest rotation methods and practices.

Advancements in technology have made managing inventory and implementing stock rotation systems easier. Many restaurants now use software that tracks inventory levels and expiry dates and helps plan stock rotation. This technology can significantly reduce the time and effort required to check and rotate stock manually.

It’s crucial to monitor and adjust the rotation system as needed regularly. Market trends, customer preferences, and seasonal changes can all affect stock rotation. Businesses should be flexible and willing to adapt their rotation methods to ensure they always operate as efficiently as possible.

Different foods require different rotation strategies. For example, fresh produce might have a different rotation system in a grocery store than canned goods. Perishable goods, like meat and vegetables, should be stored to allow easy access and visibility of dates. Non-perishable items have a more extended shelf life but require rotation to ensure the older stock is used first.

The stock rotation process is a way to organise and manage inventory and is critical in reducing stock loss and minimising waste. By managing inventory and ensuring that older products are sold or used before they go out of date, businesses can significantly reduce the amount of stock that becomes unsellable. Stock loss mitigation reduces costs and contributes to environmental sustainability by minimising food waste.

Despite the best efforts, there will be times when the stock goes out of date. In such cases, it’s essential to have a process for handling out-of-date stock. This might include discounting the products for quick sale, donating to food banks, or proper disposal if the products are no longer safe to consume.

When engaging in stock rotation within a hospitality setting, like a restaurant or kitchen, it’s advisable to wear appropriate clothing that prioritises hygiene and safety. Chefswear, including a chef’s coat and pants, is ideal. A chef’s coat offers coverage and safeguards against potential contamination of food items. In contrast, chef’s pants provide comfort and durability for tasks that often involve bending, lifting, and moving stock items.

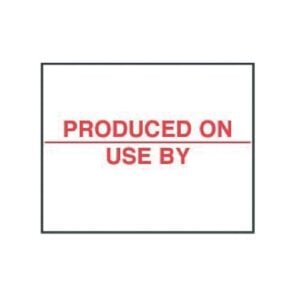

Proper food labelling, especially regarding date labelling, is crucial in ensuring that the food served is not just delicious but safe for consumption.

Labelling food appropriately in a restaurant isn’t just a regulatory requirement; it’s a critical measure for food safety. Accurate food labels, including use-by dates and allergy warnings, help prevent the risks associated with foodborne illnesses and allergic reactions. For instance, allergy sufferers rely heavily on food labels to avoid ingredients that could trigger a fatal response.

In the aftermath of Brexit, there has been a substantial shift in food regulations that require restaurants to stay informed. These regulations consist of a blend of local, national, and, at times, European Union directives. A prominent example is the Northern Ireland Protocol, which specifically addresses the movement of goods, including food, between Northern Ireland and the rest of the UK. Restaurants must possess a thorough understanding of these regulations to maintain smooth operations.

Understanding the difference between ‘use by’ and ‘best before’ dates. ‘Use by’ dates are often found on perishable items like meat products, chicken fillets, and fresh fruit, indicating the safety threshold for consumption. ‘Best before’ dates, typically seen on packaged foods and dry goods, suggest the period for optimal quality.

Regarding labelling expiry dates on food products, there are several ways to do it, each serving a specific purpose.

Food allergies can be life-threatening, making it vital for restaurants to label foods that contain allergens. Common allergens include nuts, dairy products like raw milk, gluten, and other proteins. Allergy warnings should be prominent on mass caterers’ prepacked food and delivery documents.

Food packaging should not only protect the product but also provide essential information. This includes nutrition labelling, details about genetically modified ingredients, and whether the product suits vegetarians. For certain products like beef burgers or sausage rolls, additional information on the origin of the meat (animal species) and any treatment like heat treating might be required.

Using only specific colours and maintaining a minimum font size ensures that labels are legible. Consistent label formats across food products facilitate easier identification and understanding for staff and consumers.

Staff in restaurants should be trained in understanding and implementing food labelling requirements. This includes knowledge about potential organisms harmful to health, the implications of ingredients like sugars and aspartame, and the proper way to label foods treated with ionising radiation.

Restaurants must know the differences in labelling requirements for local and imported foods. For instance, EU rules may differ from local regulations. Items, like reformed scampi pieces or Cornish pasties, might have specific compositional standards and labelling requirements.

Vegetarian dishes and options for allergy sufferers should be clearly labelled. This includes indicating any cross-contamination risks and providing alternative options where possible.

Specific labelling rules apply for foods like prepacked food or animal by-products. These might include providing the physical address of the final consumer, ensuring clear product descriptions, and adhering to origin rules.

Utilising software for label creation can ensure compliance with regulations like mandatory information on genetically modified or irradiated ingredients. This technology can also aid in tracking the shelf life of products and managing inventory effectively.

It’s about ensuring the safety and satisfaction of the final consumer. From managing the shelf life of ingredients like fresh fruit and raw milk to catering to the specific needs of allergy sufferers, restaurants have a significant responsibility. By adhering to local and EU regulations, understanding the nuances of food labelling, and implementing best practices, restaurants can ensure that their food products are not just delectable but also safe and compliant. Remember, the key to success in the food business lies in the details – and food labelling is one detail that cannot be overlooked.

Companies can ensure product quality, reduce waste, and optimise profitability by implementing a robust rotation, a labelling system, training staff, utilising technology, and regularly reviewing processes. This proactive approach to stock management benefits business operations and contributes to a better customer experience and a more sustainable environment.

To learn about maintaining a clean kitchen, check out our blog all about sanitation by clicking here.

A Company Registered in England & Wales Company Registration Number: GB05069286 VAT Registration Number: GB867112521 Smart Hospitality Supplies is a trading division of The Smart Marketing & Media Group Limited